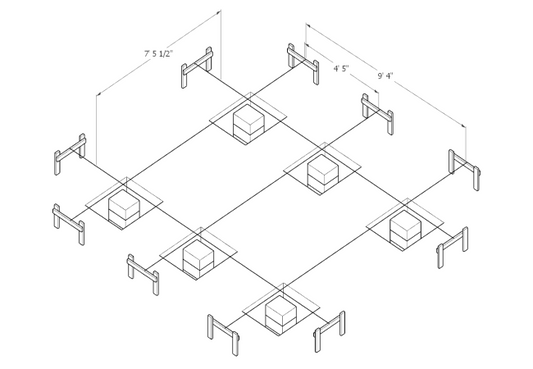

Sauna Timber Frame

Once the sauna floor is built we can get down to the most pleasant stage of sauna construction - putting up the sauna timber frame. I say that this is the best stage, because the sauna grows right in front of you - if we have all tools and materials prepared, it will take two people a few days at most to put up the whole structure.

What do we need to start building a sauna timber frame?

- the beams must be treated (for example, with rot resistant timber paint)

- screws, tools and hardware prepared

Stopping work in the middle of it and going to the store for more screws, for example, significantly slows down the entire construction process, so it is worth preparing everything in advance.

I will describe our building process for Sauna Tuula. We started building the structure from the longest wall. We cut and set all the necessary studs flat on the floor according to the design. We screwed the studs together with wood screws 4,5 mm X 90 mm.

Bracing - a way to make a stable timber frame

Where it is specified in the design, we need to add bracing. The bracing stabilizes the wall against dynamic loads, mainly wind load. We used a board about 25 mm thick and 250 mm wide, as a bracing element. First we laid the board on our wall structure, then with marked out on the beams the places where the bracing board meets the beams. We cut out such marked places to a depth equal to the thickness of the board - that is, 25 mm. We used a circular saw for wood and a sharp, wide chisel to make the cuts. First, we set the saw to a depth of about 26mm and cut grooves. The more grooves, the better, because later it will be easier for us to carve out the recesses with the chisel.

It is important to remember that the recesses should fit 'tightly', this will strengthen the joint, as well as the entire sauna frame. When all the recesses are chiseled, we screw our prepared brace, preferably with 2 screws, on each joint.

When the whole wall is ready, we can put it upright. Before we put it up, it is a good idea to screw the battens to the wall, which will temporarily anchor the wall. We don't want the wall to fall over once we put it up. We screw the wall to the floor with screws every 15 cm or so. When one wall is ready, we can begin with the next one. Finally, we fix the top plate on top of the walls. The top wall plate holds the walls together.

Sauna roof structure

When we finish the ground floor walls, we will need to build the roof structure. Depending on the design, the roof can be ‘flat’ or gabled. The best way to create a roof truss is to make a template, and prefabricate it on the ground, before raising it into position. By making all the roof trusses on the ground using a template, we ensure the dimensions of each one are the same. It is also much easier to build them on the ground and then to hoist them up. The roof structure should also be braced against lateral loads. To do this, we used a steel strip nailed across the roof structure in an X shape . The metal strips were attached to every truss with nails. At this point, it is important to remember to keep the length of the truss beams according to the design. We made the mistake of leaving them too long, and later we had to cut them shorter.

When the structure is finished, the sauna building is ready for the next construction stages: Breather membrane.